Nailing it Down: Completing the study of the metal fastenings of the Kyrenia Ship - 2017

Wendy Van Duivenvoorde

The early 3rd-century B.C. shipwreck at Kyrenia, Cyprus, was excavated in its entirety in 1968–1969 and provided the remains of a well-preserved Mediterranean merchant ship and its cargo. The ship sank in the first decade of the 3rd century B.C (c. 295–285 B.C.), but was built sometime towards the end of the 4th century, between 315 and 305 B.C.

For this project, the recipient studied over 3,000 metal fasteners found, mapped, and raised from the Kyrenia shipwreck site in Cyprus. The project aimed to reveal for the first time through interdisciplinary study how an archaeological legacy collection, excavated from a shipwreck site in the late 1960s, creates new knowledge and interpretation of culture, procurement of raw materials, and their manufacture into shipbuilding materials. It provides an insight into the smelting technology used in the production of the fasteners, their manufacture and the technological skills of the people who worked on shipyards when the Kyrenia Ship was built, sailed, repaired, and maintained in the eastern Mediterranean basin.

Methodology

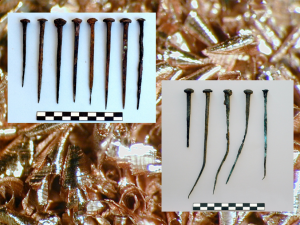

The Kyrenia Ship’s remains include c. 75% of the structural members of its hull, along with elements of its rigging and sail, and fragments of a one-armed wooden anchor with a lead-filled stock. The ship’s assemblage of fasteners includes mostly cupreous ship nails that fastened the frames to the hull planking and other constructional elements of the vessel. In addition, cupreous tacks were found to fasten the ship’s lead sheathing to its hull planking. Other fasteners, found in the ship’s stern cabin, include a sack of miscellaneous small iron nails found as an individual concretion, spare ship nails, and a scatter of iron mushroom-headed nails.

The recipient travelled to Cyprus in April 2018 to record and study the collection of the aforementioned Kyrenia Ship fasteners. All fasteners were measured, recorded and photographed and entered into the Kyrenia ship fastener database. This fieldwork completed the data collection of the entire Kyrenia ship nail assembly.

The objectives of this project also included a comprehensive analytical approach for the identification and provenance of all the ship’s preserved metal fasteners. The methods applied include their recording, identification related to function and material composition, and a metallographic examination of a representative selection of nails. The techniques to analyse the fasteners consisted primarily of Scanning Electron Microscopy (SEM) with EDS Analyser to identify the metals and their composition, and Multi-Collector Inductively Coupled Plasma Mass Spectrometry (MC-ICPMS) for provenance studies using lead isotope analyses.

The samples were analysed by the recipient at Adelaide Microscopy, South Australia, using a FEI Quanta 450 FEG Environmental Scanning Electron Microscope (ESEM)(https://www.adelaide.edu.au/microscopy/instrumentation/quanta450.html). The FEI Quanta 450 is a High-Resolution Field Emission Scanning Electron and is used to image and analyse surface topography, collect back-scattered electron images and characterise and determine a sample’s elemental composition through x-ray detection with an SDD EDS detector.

ICPMS and lead isotope analyses for this project were undertaken by José I. Gil Ibarguchi and Javier Rodríguez Aller (Servicio de Geocronología y Geoquímica Isotópica, SGIker- Facultad de Ciencia y Tecnología) at the Universidad del País Vasco, Leioa, Spain.

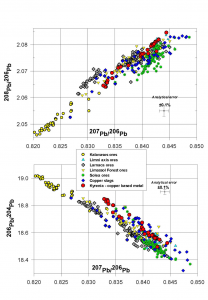

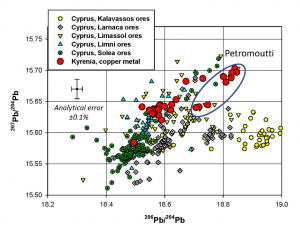

Comparison of the lead isotope data with the Oxford Analysis Lead Isotope Database by Sophie Stos revealed that the samples from the Kyrenia ship fasteners, i.e. nails and tacks, are consistent with the range and linearity of lead isotope data for the ore deposits on Cyprus, as can be seen on the plot of the radiogenic and non-radiogenic lead isotope ratios (Fig 2)

Summary of results

The Kyrenia Ship’s assemblage of fasteners includes mostly cupreous ship nails that fastened the frames to the hull planking and other constructional elements of the vessel. In addition, cupreous tacks were found to fasten the ship’s lead sheathing to its hull planking. Other fasteners, found in the ship’s stern cabin, include a sack of miscellaneous small iron nails found as an individual concretion, spare ship nails (Fig. 3), and a scatter of iron mushroom-headed nails.

Of the 50 samples extracted from the Kyrenia ship’s fasteners 49 were suitable for analyses to identify the exact material composition using ICPMS and SEM EDAX analyses, i.e. the metallic sample material allowed for accurate analyses. The samples were tested positive for the following elements: Fe (iron), Cu (copper), Pb (lead), Sn (tin), and Zn (zinc). The amount of copper in the samples varied between 95.88 and 99.61% (with the fast majority around 99%). The concentrations of natural impurities found in copper, such as iron, nickel, zinc, lead, antimony, and arsenic, were generally found to be less than 1%.

This project examined the archaeological, material chemistry, and historical evidence derived from the metal fasteners used in the Kyrenia Ship’s construction in order to ascertain the manufacturing process by which they were made and to draw conclusions on their broader socio-economic context. The accurate identification and contextualization of these metal fasteners provided valuable information for a more precise reconstruction of the original ship’s size and a better understanding of the shipbuilding industry and materials it used, as well as ancillary industries associated with boatbuilding.

Copper seems to have been the preferred metal over bronze or iron for the production of nails in the Archaic and Classical periods, even though bronze (an alloy of copper and tin), or alloyed arsenic copper would have been harder and more durable than unalloyed copper. The copper used in the Kyrenia ship’s construction originated from several deposits on Cyprus. The majority of the Kyrenia samples (28) is consistent with the ores from northern deposits near the village of Limni and in the Solea (Apliki and Mavrovouni). The second large group (13 samples) is fully consistent with the ores and slags found in the region of Petromoutti-Yerasa in the Limassol Forest.

Future Research plans

The Kyrenia Ship fasteners project will continue with a study of the distribution pattern of all loose and detached fastening (i.e. from their original upper hull or superstructure timbers, long disintegrated). The aim is to determine how many more planking strakes need to be added to reconstruct the original height of the ship’s hull more accurately. This will seek to contribute to the late J. Richard Steffy’s pivotal study of the Kyrenia Ship’s hull and work towards a monograph publication.